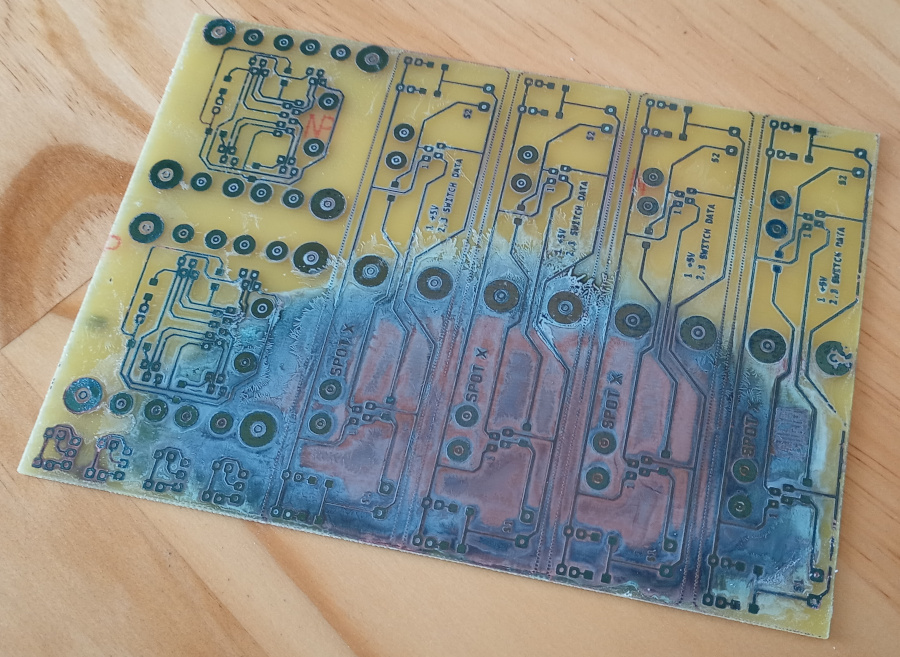

This is what happened after trying to make some PCBs for my new robot.

I had one blank PCB left from years ago and maybe just enough etchant to do the job, but things didn’t go to plan.

I’d redesigned the front and rear bumpers so that the same design can be used on the left or right side. I also designed an aggregator PCB to bring all the switch lines to a single RJ45 jack to interface with the control board. The printout was okay but seriously, my inkjet does a pretty terrible job of it so I was actually looking at laser printers.

Before I began the etching process I’d examined the transparency and noted a fair bit of ink spatter surrounding the traces. I don’t think this helped the clarity of the finished product. That’s one of the reasons a laser print would be so much better.

Anyway, exposure and development went well enough so I proceeded to do the etching.

Things were going pretty slowly. Without the immersion heater I was having trouble keeping the temperature high enough. I kept having to tip the etchant out and microwave it.

Here’s where I made the fatal mistake. I had a little bit of etchant left in the bottle so I decided to tip it all in, except that the developer bottle looked identical and I poured a bunch of developer into the tank.

I don’t know what that did to the chemistry, but it filled up with pale blue flocculant that I didn’t understand until I realised my mistake. Once I’d figured out that I’d poured in the wrong chemical, I poured the mix through a sieve and added the last of the etchant.

It didn’t help.

So I left it for a day before trying again. I heated up the mix and got the air pump going and after hours (!) it looked like things were progressing. Large areas of the board started clearing and I thought I was in with a shot.

Then I examined the board. In areas where the etching was almost complete, the photoresist had almost disappeared and there was still a lot of copper between the traces and pads. I figured there was no way of etching the rest of the board before the etched areas eroded completely.

Anyway, after noticing the severe problems with the board I called it quits and gave up.

That’s probably where things would have stayed except for a clumsy accident. I was getting my 3D printer going again and plugged the USB cable into my computer. 3 seconds later I tripped over the cable, snapping the USB connector and the PCB it is attached to.

This is the front panel connector PCB. I had a look at it and there wasn’t really any way of repairing it, except maybe soldering wires between pads and gluing the thing together. (foreshadowing)

I hemmed and hawed for a bit, examined the board, and decided that I could build a replacement. I didn’t want to buy a new computer case and the front panel connectors are kind of important.

So I’ve ordered some new blank PCBs and some etchant. I’ll have a go at fixing the computer and then finish the boards for the robot after all. We’ll see how it goes.

Originally written September 17, 2025